This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

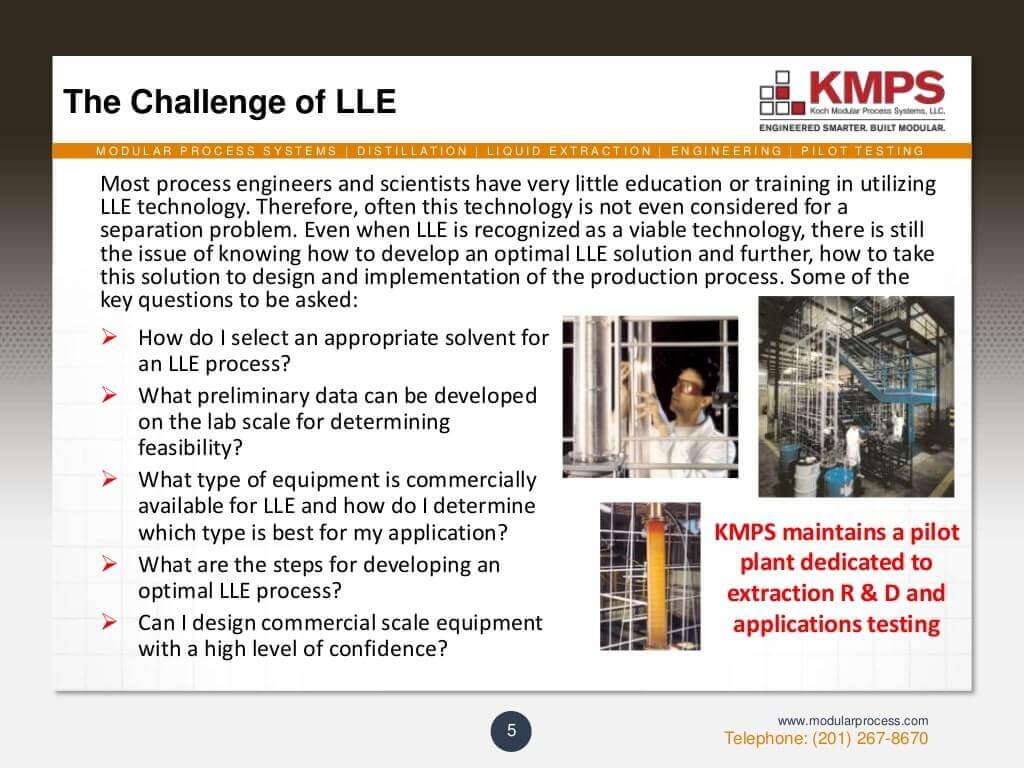

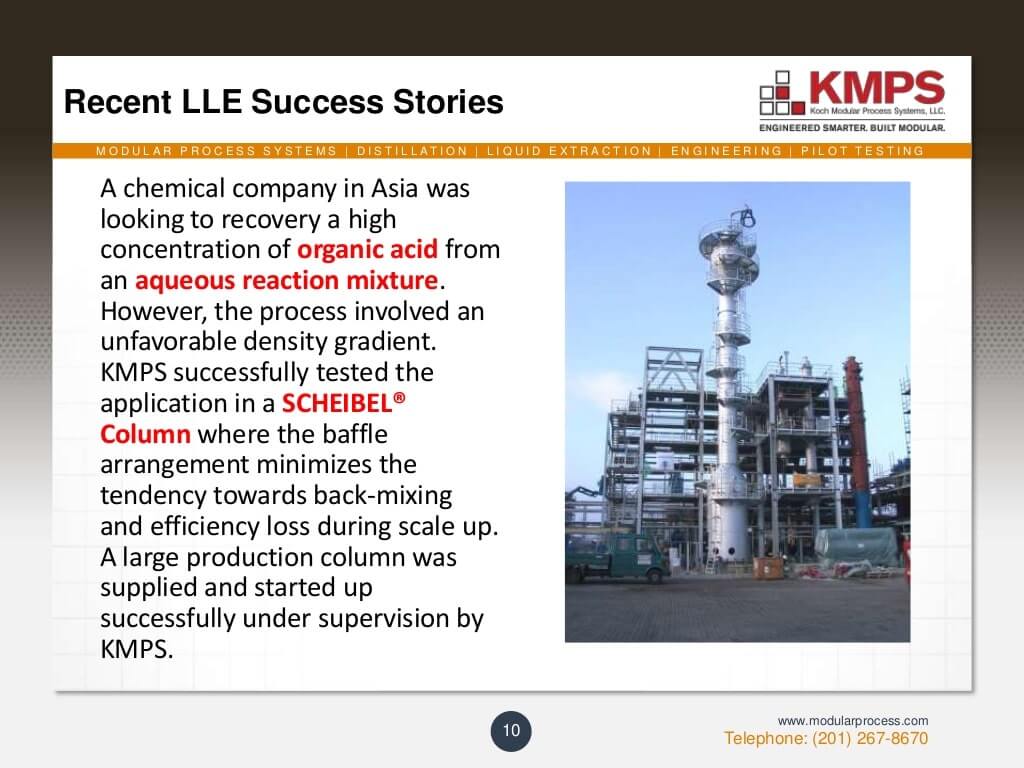

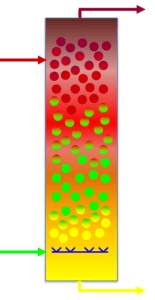

Koch Modular offers a broad range of laboratory and pilot plant liquid-liquid extraction equipment to assist you during feasibility studies, process development and equipment design stages of your project. The picture to the right shows a pilot-scale extraction column. Typically we supply the column with internals mounted to a stainless steel support frame along with the variable speed drive.

Our equipment is available on either a sale or rental basis and includes the following:

- Laboratory scale extraction columns to screen solvents, evaluate feed variables and determine the feasibility of liquid-liquid extraction for specific applications.

- Small pilot scale columns (static and dynamic designs) to optimize the extraction parameters and provide accurate data for scale up to commercial equipment.

- Large pilot columns for semi-works or small scale production facilities.

- Portable units, which can be rented for testing on site.

Koch Modular can provide trained service personnel to assist you in installing the pilot extraction column at your facility. Koch Modular is also available to help you set up an effective pilot plant test procedure and will work with you to optimize the column performance. We will also interpret the test results and apply them to the design of your commercial column.

As a world leader in LLE technology, Koch Modular has developed hundreds of commercial liquid-liquid extraction columns and systems

For more successful case studies by Koch Modular, check out our White Papers and Presentations.

Agitated Columns

Koch Modular offers a number of agitated liquid-liquid extraction columns. These columns are normally provided with a borosilicate glass shell for observation of the process. Such observation is critical for optimization of the column performance. The standard designs are the 1″ diameter KARR® Reciprocating Plate Column and 3″ diameter SCHEIBEL® and RDC columns.

Static Columns

Koch Modular also offers a 4″ diameter static column packed with either SMV or SMVP extraction packing. This unique packing promotes good radial mixing while suppressing axial (back) mixing providing better plug flow characteristics and improving efficiency compared to random packing. The pilot column is offered with a glass shell (atmospheric pressure operation) and stainless steel shell (for operating at elevated pressures).

Bench Top KARRⓇ Column

For lab scale feasibility studies, Koch Modular can also provide a Bench Top KARR® Column that consists of a 5/8″ diameter glass column with a 24″ plate stack height. Two plate stack assemblies are included (316SS and Teflon perforated plates and spacers) with 1/2″ plate spacing. An air motor is provided to regulate the agitation in the column. The unit comes in a stainless steel frame as shown in the picture below. Koch Modular has demonstrated that up to 2.7 theoretical stages per foot of agitated height can be achieved with this unit. Please contact us for ordering information.

Extraction Screening Unit

Sometimes the nature of process materials being handled prohibits testing at our pilot plant. In these cases, Koch Modular can deliver portable units and operating personnel to the plant for on site testing. One such unit is our portable Extraction Screening Unit (ESU) ideally suited to simplify on-site testing, see picture to the right. This unit consists of a 3″ diameter x 12 – 18 stage, SCHEIBEL® Column with glass shell and air drive motor. Two stainless steel tanks with sight glasses and rotometers for flow control are mounted with the column onto a portable frame. Powered by air or nitrogen, it is ideal for use in hazardous areas.