This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Challenge

Due to the increased height of the new column, the client was concerned if vertical tolerances were not maintained, slight variations in vertical deflects could impact operations. Therefore, great care was taken to ensure the column was fabricated and installed perfectly vertical without deflection.

During fabrication and installation various laser measurement were taken throughout the process to ensure alignment. Another challenge included the design and fabrication of the 5” internal shaft fabricated in Hastelloy.

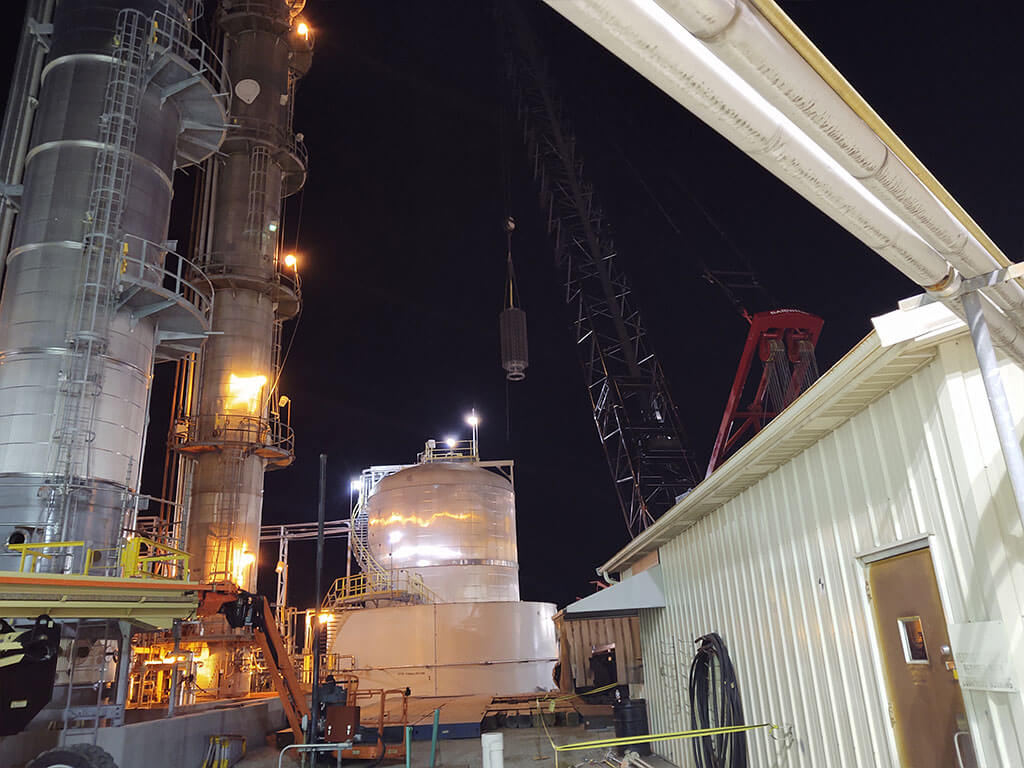

Additional precautions were taken to prevent thermal expansion by performing installation activities during night operations

SOLUTION

In order to facilitate preliminary engineering and the calculation of the correct number of theoretical stages of the replacement SCHEIBEL® Column, a rental column was shipped to the client facility for onsite pilot testing.

Results were analyzed by Koch Modular process engineering and a commercial scale up was developed and allowed for the issuance of a process performance guarantee.

RESULTS

The new standalone column designed to extract organic chemicals from an aqueous solution reached a staggering 130 feet in height and 10 feet in diameter. At 130’, this makes it the largest SCHEIBEL® column delivered by Koch Modular to date.

Although this project involved several complexities beyond sheer size, such as the use of several high alloy components as well as thermal expansion considerations, the project was successfully delivered within 18 months beginning with pilot testing, through engineering, fabrication, and delivery. Furthermore, this column was operational and online ready to supply the market within a month and a half from delivery.

Ultimately, the new SCHEIBEL® Liquid to Liquid Extraction column delivered outstanding results by increasing capacity by an estimated 75% while keeping the same solvent to feed ration and recovery for future decades.